HOME COACH HISTORY DEPARTMENTAL USE RESTORATION - 1 RESTORATION - 2 RESTORATION - 3 RESTORATION - 4 RESTORATION - 5 RESTORATION - 6 RESTORATION - 7 THE FUTURE

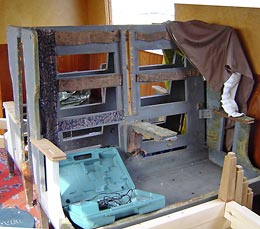

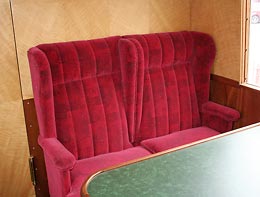

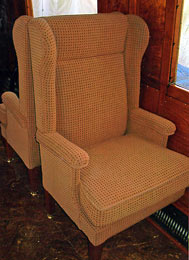

7960 Restoration Update January 2008The Electrics When restoration commenced on 7960 at the end of 1990 little remained of the original electrical system. There was one Stones exhauster fan in the kitchen and a refrigeration unit housed in a cabinet hung directly underneath the pantry floor, but apart from severed cable runs that was it, not even a solitary bulb holder. Being total ignorant of all things electrical I had little idea as to how to proceed, but two chance visitors helped to save the day. The visits occurred whilst 7960 was on the jacks in the mechanical workshop having numerous gas cabinets removed. The first visitor was an official from the Bristol Harbour Railway who kindly donated a dynamo, voltage regulator and various fuse boxes from a Mk1 Full Brake that was being used as a static store. The second visitor was Graham Gardener a volunteer member of the SVR S&T Department. Usually Graham could be found perched up a telegraph pole, but his curiosity led him into the carriage workshop. On enquiring as to what was on the jacks he was told that if he helped remove the cabinets he might get an answer. Graham has been a regular member of ‘the team’ ever since and one of his principle tasks has been to install the electrics. Alleluia! Underneath the frames the first task was to install replacement metal beam supports for the battery boxes. Four sets of battery boxes were then fitted, two to house the twelve battery cells, one to house the voltage regulator and fuse boxes whilst the fourth has been left empty. Installing the four boxes has helped replicate the original appearance of 7960. Internally Graham has based the wiring circuits on a BR Mk1 Open with suitable adjustments. A through control switch was fitted in the corridor and this controls all ceiling lights in the vestibule, saloons, corridor and toilet. A separate switch cupboard donated by the SVR LNER Coach Fund houses switches that control lights in the pantry and kitchen, table lights in the two saloons and the two saloon extractor fans. Throughout this lengthy restoration various missing electrical bits have been acquired either by donation or bartering, but some items have had to be made. These include the light reflector bowls that sit flush in the corridor, vestibule and toilet ceilings. The Stone exhauster fans proved difficult to obtain. One survived, but four were required, two for the kitchen and one each for the saloons. Tests on the surviving fan indicated that it would place a heavy load on the battery supply. Therefore it was decided to construct replacements by fitting three 4 inch 24 volt fans in a circular metal plate that fitted in the ceiling opening. Fortunately two original fan covers were donated. The two fans now whirl merrily away without draining the batteries. Whilst the refrigerator unit will not be used it was decided to restore it to working order out of curiosity. The unit consists of an electric motor that drives a cooling fan and a compressor unit by belt drive and a radiator through which the ammonia gas was cooled. Once working it sounded like a 1930’s London tube standing in the platform. The unit is being retained for its historical interest. In the Autumn of 2006 SVR member Peter Maddicks arranged for the bulk purchase of new BR 19 double-post batteries for a number of carriage owning groups and individuals including 7960 for what turned out to be an absolute bargain price. The set for 7960 arrived at the beginning of January 2007 and after much huffing and puffing were installed by the end of the month. Shortly afterwards Graham completed the wiring and once again after a gap of 47 years 7960 had its own independent lighting. In October 2007 the carriage was returned to Kidderminster for the completion of the mechanical work, which included the fitting of the missing dynamo. This proved to be quite a task, as a new support bracket and tension bar had to be made and a safety chain fitted. Care in fixing the position of the dynamo on the support bracket had to be taken to avoid the dynamo belt from coming off the pulley, as the bogey travelled around a tight radius. Apart from the manufacture of the table lamps, which will begin in January 2008 the electrical restoration is now complete. Steam Heating When 7960 was converted from departmental use all the internal steam heat pipe work was removed with the exception of the feed to one of the two 35 gallon capacity water tanks situated above the corridor ceiling. This feed served a heat exchanger in the tank and gave the kitchen staff a supply of warm water. With the replacement of both tanks it was decided to remove the feed as a new heat exchanger was not considered cost effective. The main external steam pipe was badly corroded and sections had been removed. Fortunately the two end on/off valves were still in situ, normally they are the first to walk! Several years into the restoration an opportunity arose for 7960 to go into the workshop at Kidderminster. With the carriage on the jacks work was able to proceed on replacing the main steam pipe. This consisted of a 2 inch BSP galvanised pipe running underneath the centre of the coach. At each end a main on/off valve was fitted together with a drip valve to allow condensed water to escape. A similar valve was also fitted in the middle of the pipe run. Four 1 inch branches were taken off the main pipe to feed the internal heating circuits. Whilst simple in theory the work proved difficult to undertake with clearances tight, particularly above the bogies. Fortunately I was helped and guided by Colin Jenkins who throughout the restoration has been there to help, both practically and with his considerable knowledge. Mind you so he should since it was Colin who introduced me to 7960! Some years later when work on the two saloons was well advanced the internal steam heat circuits were installed. These comprise four 1·5 inch BSP pipe runs, each one running the length of the exterior saloon wall. From each external branch the steam was fed up through the floor to an on/off valve. The pipe then ran the length of the saloon wall before returning on itself. The exhaust steam and water was then vented beneath the floor. The passenger’s feet are protected from the hot pipes by grills, one below each window, these being obtained from the LNER Coach Association based on the NYMR. Again clearances were very tight, care having to be taken that the return pipe had sufficient slope for condensed water not to accumulate causing corrosion problems. Final testing of the system occurred in November 2007. A pressure reducer valve had been fitted at the beginning of each branch. This simple device consists of a brass ball in a metal housing. Incoming steam pressure holds the ball against the opening of the exit pipe, thus stopping steam from flowing. Steam is allowed to pass by cutting a groove in the ball, the bigger the groove the more steam. The ideal flow of steam results in hot water exhausting together with just a whiff of steam. All the pipe joints and there were lots! proved to be steam tight. Seating Work on providing replacement seats began in March 2007, the originals having been removed when 7960 was converted for departmental use. Fortunately there were several good official photos available of the interior of the 1st class saloon showing the style of the seats in some detail. A spare single and double seat from a BR Mk1 FO were available from the Kidderminster carriage stores and as these were found to be a good fit it was decided to obtain three further sets, an advert on The Carriage Exchange proving successful. Considerable work had to be undertaken on these seats to replicate the appearance of the originals. The most unpleasant task was stripping off the old upholstery, the dust resembling a sandstorm and then removing hundreds of staples and tacks. All the legs, which were very battered, were replaced, as were the arm supports. The side wings were reshaped. The comfortable folding arms on the double seats were removed and replaces with fixed centre wings. Two of the single seats also had to be reduced by 2 inch in width to stop them fouling the two exit doors in the saloon. With so much work having to be undertaken on the frames one was left wondering whether it would have been easier to build from scratch. The spring cushions and cages, that came with the seats were however a big bonus. The 3rd class seats had to be built from scratch using as a pattern a seat frame salvaged from LNER Brake 2nd Open 166000, which had been scrapped on the SVR many years earlier. The style of build and dimension of the timber parts closely resembled the Mk1 FO. Because of the scale of work involved it was decided to obtain the timber components cut to finished size commercially, apart from the legs, shaped arm bases and the triangular corner blocks which hold the back and side frames together. Graham Gardener produced the latter using his newly acquired Band-saw. Cutting the many mortice and tenon joints and assembling the framework for the bases and backs were done at home. The final assembly was undertaken in the saloon, the completed chair carcases could be removed from the coach ‘just’ via the end gangway door. Having gone to considerable lengths to produce seat frames, that would match the originals, it was disappointing not to be able to do the same with the upholstery. The 1st class fabric shown in the works photo appeared to be tapestry rather than the more usual moquette. Enquiries to other Gresley carriage groups drew a blank. An odd roll of moquette was available from the carriage store and this was used for the 3rd class saloon. Its subdued brown/fawn colour has, in fact, toned in well with the teak finish and the brown tops of the tables. A stock line, in red/black design from Holdsworth has been used for the 1st class saloon and again has toned in well with the mahogany finish and green table tops. The fluted style of the seat backs, as with the originals, is particularly attractive. Following steam heat tests the seats were permanently installed by the end of December 2007. Bogies and Brake System Towards the end of October 2007 7960 was moved from Bewdley into the mechanical workshop at Kidderminster to have the mechanical repairs either tested, adjusted or completed. The first job was to re-unite 7960 with its own bogies. These together with the associated brake rigging had been overhauled some years earlier and for a time ran under LNER Buffet 643 whilst its own were being repaired. The bogies and rigging were cleaned, painted and adjusted before re-uniting them with 7960. New wooden steps were made and fitted. The buffer heights were then set by adjusting the springing. The uneven weight distribution of the body made the task difficult. The two vacuum cylinders were overhauled and tested before re-fitting. The two brake shafts were removed and cleaned and the holes re-bushed before re-fitting. The drawgear and the buckeye couplers were checked and adjusted, the latter having new operating chains fitted. The corridor connection heights were also adjusted. Needless to say much of the work was both specialised and skilled and was undertaken by Nigel Hanson and Eric Southan of the full-time staff. It is true to say that in the early days of carriage preservation and restoration efforts tended to be concentrated on exterior bodywork and the interiors. The mechanics tended to be ignored, a coat of paint often covering up a multitude of sins, not so with 7960. Thanks to the interest and efforts of Nigel and Eric and others I can confidently state that the mechanical condition of 7960 is now as good as the day it left Doncaster works. |

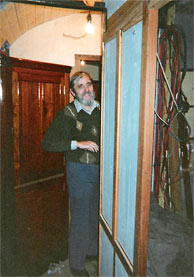

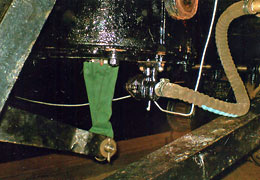

Graham Gardener working on the electrical installation. Homemade version of a Stones’ exhauster fan. Cabinet holding the refrigeration unit - sounds like a London Tube! A BR FO Mk1 seat before modification. The same seat after modification and re-upholstering One of the double FO seats stripped down for rebuilding. After rebuilding and re-upholstering with fixed centre wing Two of the third class seat bases. The seating progressing in the third class saloon. Phil assembling one of the third class seat frames. The third class seating upholstered in a subdued brown/fawn colour moquette. Pipe circuit showing the pipe entry, control valve, grill and return pipe. The two bogies stripped down for inspection and repainting in Kidderminster carriage works. Overhauled a few years back they then run for a while under LNER Buffet 643. The checked and adjusted drawgear and buckeye couplers. One of the two vacuum cylinders, overhauled, tested and re-fitted. Work beneath the gangway connection completed with all the various bits dangling in the right places |

|||